Class opens the door to a new world of mechanical engineering

When Peter Williams was taking 2.002 (Mechanics and Materials II) this past semester, he won a trophy whose height is approximately equal to the width of three human hairs. Rather than feeling short-changed over his minuscule prize, the senior in mechanical engineering considered it a fitting award for a contest in which he and his classmates were asked to design a nanoscale material able to withstand compression.

The design challenge represents an innovative new part of the undergraduate class on the mechanical properties of materials. While 2.002 traditionally includes classical lab experiments, Professor Carlos Portela wanted to give students a hands-on research experience at the exciting frontier of their field.

“The objective was not only to expose students to leading-edge concepts of nanotechnology, nanomechanics, and metamaterials, but particularly for them to be in the ‘driver’s seat’ of this experience,” says Portela, who is the d’Arbeloff Career Development assistant professor in MIT’s Department of Mechanical Engineering. “We were convinced that a design challenge — where students would invent new 3D designs of metamaterials, observe and participate in the fabrication and characterization processes, and have a friendly competition against their peers — would achieve just that.”

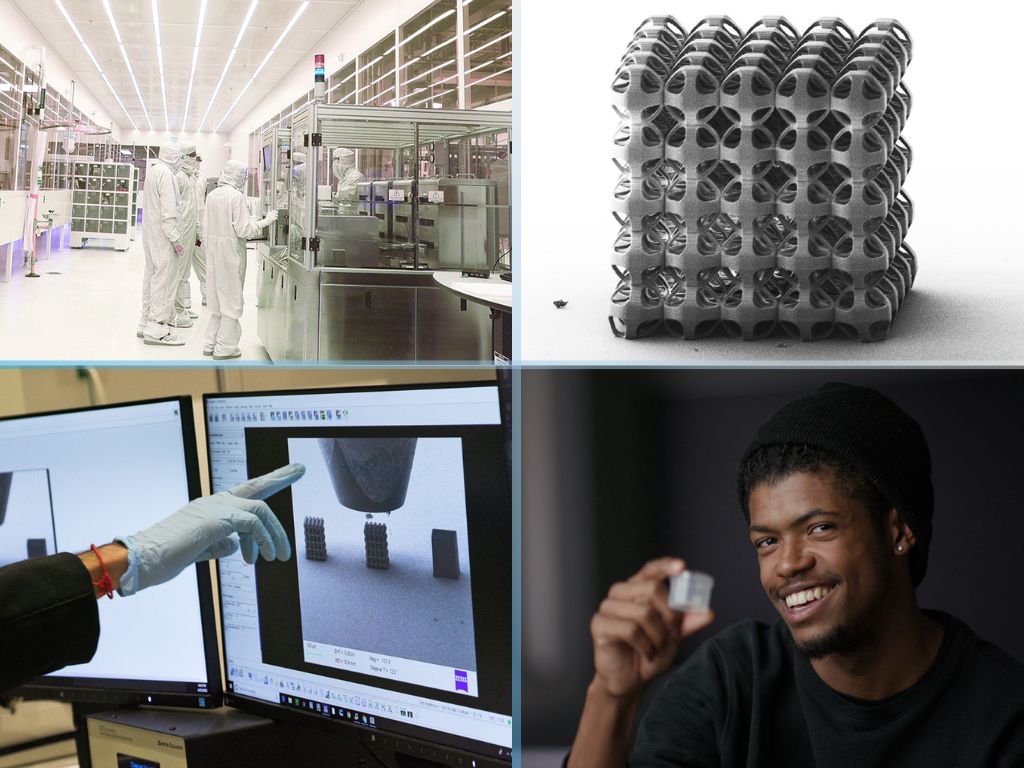

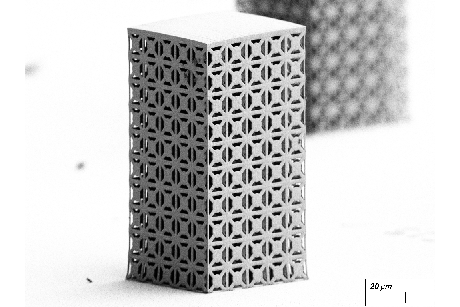

The design challenge brought students into a lab at the world-class MIT.nano facility, an environment so delicate that all who enter must first cover themselves head to toe to try to keep out even the most minute speck of dust. Their mission was straightforward: to design the most compression-resistant microscopic cube possible with a material that would touch each side of the cube but fill only 20 percent of the total volume. The materials were fabricated using a 3D printer that shines a laser on resin to create precise, high-resolution structures.

“We were able to architect microscale metamaterials [materials designed to have certain mechanical behaviors] and come up with some really interesting designs and findings from that,” Williams says, adding that he appreciated the experience of working on “the questions that real scientists are asking currently.”

For his winning entry, Williams relied on a design principle he had learned before taking 2.002. Calling it a “clear way to win,” he arranged his nanomaterial in a two-dimensional profile that looks like vertical walls.

“If you have some kind of truss structure, it’s not going to be as good as if the material is directly supported by the material under it. You can’t put the same material diagonally and expect it to be as strong,” Williams says. “I’m very good at CAD, and this is a very simple design. The more complicated ones didn’t work.”

Senior Allison King designed her material using hexagons, which are also known to withstand compression really well. King’s material came in second, and although she was a bit disappointed she didn’t walk away with the nearly invisible trophy, she expresses enormous excitement in having participated in the competition and experienced the MIT.nano lab.

“You walked in the lab, and it made you realize in that moment that, wow, MIT is a very cool place,” King says. “People are literally pushing the bounds of engineering right in front of you and right now.”

King says she was “on the edge of my seat,” as her material, made visible with an electron microscope, was shown on a monitor while undergoing compression.

“I love the design side of mechanical engineering and getting to test hypotheses,” she says. “So, being given a whole lot of freedom — like, ‘Hey, go design anything you want and see if it works,’ — actually put to use the skills and training that we’ve been learning to see if we can actually build a product.”

While the design challenge was fun and exciting for the students, the process they were participating in has profound implications, Portela says. Nanomaterials can be created to have “exotic” mechanical, thermal, and even electronic properties, he says. Ceramics can be engineered to be like rubber, metals can be made stronger, and glass can become extremely durable. Nanostructures can also be made to interact with light, sound, or electrons.

“Nanoarchitected materials have the potential to address unsolved societal and engineering challenges, since they achieve combinations of properties that no existing material could ever attain. The ability to produce materials that possess nanostructures in large volumes could have an impact on a variety of fields,” Portela says. “Enabling these properties beyond the nano- or microscale will be game-changing,” he says, adding that “a lot of hard work remains to be done to get us to that point.”

For Williams, 2.002 and the design challenge may be personally life-changing. Currently planning to work in industry after he graduates, the experience is making him consider returning to academia.

“As an undergrad taking 2.002, I was able to do very graduate-level research and use very high-level facilities,” he says. “It got me excited to potentially go back into research.”

This article appeared in the Spring 2024 edition of our magazine, MechE Connects. For more stories, and for past issues, please visit meche.mit.edu/magazine.